CONTROL VALVES

TECHLINK NON METALLIC FLOW CONTROL VALVE

CT Type

Compact Low Flow

This CT type covers flows of 5 liters/h to 10 m3/h under 1 bar ΔP, with either a linear response, or an Equal Percentage response

Range : DN15-DN25

Design advantage : The one piece piston and disc design gave outstanding mechanical link between the positioner and the throttling area, for the best precision and stability.

N Type

Bellow sealed

Same performance to CT type. with polymer bellow sealing.

Range: DN15-DN25

Design advantage: N Type have sophisticated seals to guarantee a safe and leakage free service, compliant with ISO 15848-1 Class A-RT.

V type

Ball valve type

With our partner SAFI FRANCE, the V type covers flows of 1 m3/h to 150 m3/h under 1 bar ΔP.

Our specially designed V Orifice plate, gives a long lasting and precise flow control.

Range: DN25-DN150

Design advantage: V ported polymer ball valves offer best in class resistance to corrosion/erosion with great flow control at an attractive price.

Benefits

Economical with an attractive price and low maintenance.

Erosion and corrosion resistant.

Low pressure recovery (high FL factor).

Lightweight and mechanical strength.

Excellent regulation performance.

Applications

Industries:

- Chlor-Alkali Plants

- Water treatment plants

- Paper pulp mill

- Battery materials plant

Typical fluids:

- Brine

- Wet chlorine

- Hydrochloric acid

- Caustic soda

- Sodium carbonate

- Sodium hypochlorite

- Ferric chloride

- Zinc sulfate

- Copper chloride

- Sodium chlorate

- Sulfuric acid

- Chlorine dioxide

- Sodium sulfite

- Bromine

- Lime water

- Aqua regia

- Copper sulfate

- And more!

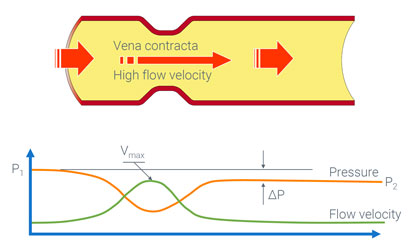

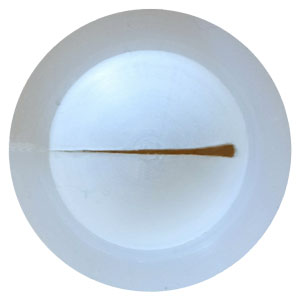

The "Vena Contracta"

Any type of flow control valve has a restricted passage area called “Vena Contracta”. In this area, the flow is accelerated to a high speed. Turbulence is created, dissipating energy and therefore creating the desired ΔP. Where the flow velocity is high, corrosive chemicals cause all sorts of damage to the materials.

Download our learning resource below to understand better the Vena Contracta phenomenon, its consequences, and our solutions.

V-Orifice seats and Needle valves

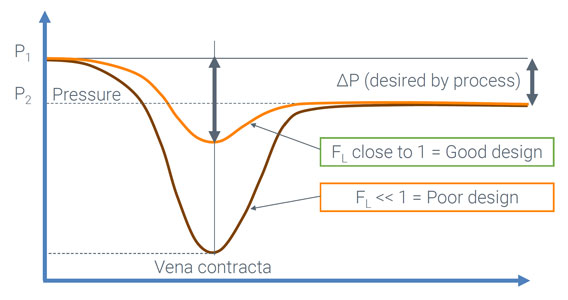

Depending on the type of valve (globe, diaphragm, butterfly, V-port ball, etc.) the pressure drop in the Vena Contracta will be more or less pronounced. A big pressure drop induces high flow velocity. High flow velocity in the Vena Contracta is what causes damage in corrosive and abrasive media.

Globe valves have a shallower pressure drop in the Vena Contracta than diaphragm , butterfly and full port ball valves.

But with proper design, V-orifice ball valves have a pressure drop as shallow as a globe valve. The pressure drop in the “vena contracta” is characterized by the “Pressure Recovery Coefficient” FL of the valve. The value of FL varies between 0 and 1. A value close to 1 means a smaller pressure drop.

The velocity in the Vena Contracta varies in the opposite way to the pressure drop. Globe and V-Orifice ball valves therefore have a lower maximum velocity in the Vena Contracta. Diaphragm and butterfly valves are the worst.

Thanks to their unique design, TECHLINK V-orifice ball and needle V-notch valves have a FL similar to Globe valves.

|

Type of valve

|

Typical FL values

|

|---|---|

|

Globe control valve CT & N type

|

0.8 ~ 0.98

|

|

TECHLINK needle V-notch

|

0.95

|

|

TECHLINK V-orifice ball

|

0.8 ~ 0.9

|

|

On/off ball valve (full bore)

|

0.7

|

|

Segmented ball

|

0.6 ~ 0.7

|

|

Butterfly

|

0.6 ~ 0.7

|

|

Diaphragm

|

0.5 ~ 0.6

|

|

Globe control valve

|

TECHLINK needle V-notch

|

TECHLINK V-orifice ball

|

On/off ball valve (full bore)

|

Segmented ball valve

|

Butterfly valve

|

Diaphragm valve

|

|---|---|---|---|---|---|---|

|

0.8 ~ 0.98

|

0.95

|

0.8 ~ 0.9

|

0.7

|

0.6 ~ 0.7

|

0.6 ~ 0.7

|

0.5 ~ 0.6

|

Why Polymer material?

The corrosion resistance of metals is generally determined in still fluids. But at high flow speeds and in the presence of turbulence, a process known as “erosion induced corrosion” starts destroying even the so-called “corrosion resistant” metals. In such situation, solid polymers offer an economic solution that will outperform even “special metals” and other exotic materials.

Taber Abraser

Apart from polyamid, which cannot be used because of its low chemical resistance, the best abrasion resistant material is PVDF. This material should be preferred for all parts of the valve making up the “Vena contracta”. When PVDF cannot be used for chemical reason, such as in concentrated hydroxides, then PPH and ECTFE are acceptable alternatives.

It is readily seen that PTFE, which has the lowest abrasion resistance of all polymers, is the worst choice for contact with the flow in the Vena Contracta. However, because of its almost universal chemical resistance, PTFE is often found as a liner in control valves, either globe valves or diaphragm valves. Such valves suffer a fast deterioration of the flow throttling parts, such as discs, seats, diaphragms etc.

|

Materials

|

Weight loss mg/10000 rev.

|

|---|---|

|

PVDF homopolymer SOLEF®

|

5 - 10

|

|

PVDF SOLEF® 21505/31508

|

5 - 8

|

|

PA 6 polyamid

|

5

|

|

ECTFE Halar ®

|

13

|

|

PP homopolymer

|

15 - 20

|

|

PTFE

|

500 - 1000

|

|

304 stainless steel

|

50

|

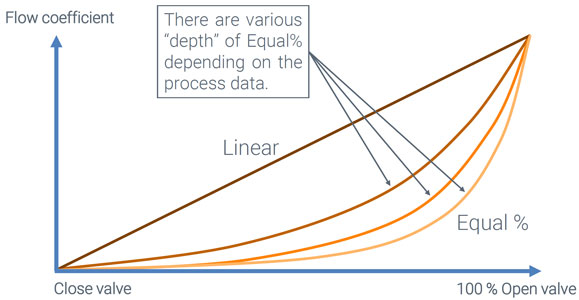

Characteristic curves

The characteristic curve must be adapted to the process. There are various “depth” of Equal% depending on the process data.

Techlink valves offer adapted orifice and needle profiles that are designed according to customer-specified process conditions for the best results. And if you are not sure which design you need, Techlink engineers are here to help you.

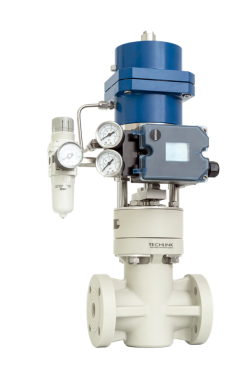

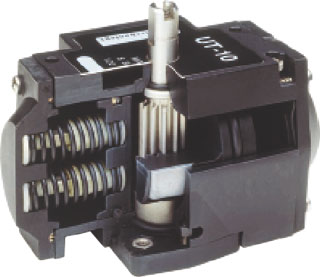

Positioner and actuator

Non-metallic components are preferred for corrosive environments. Hence, Techlink valves come with corrosion resistant accessories. Techlink engineers have experienced the best results with the positioners Samson (made in Germany) with polyphthalamide casing, Piston actuator for Globe valve CT type, Diaphragm actuator for N type and Max-air (Italy) Rack and pinion actuator for V type.

All Techlink designs can be adjusted to customer specifications.

Tested and approved!

Plant: Aditya Birla Chemicals, Thailand.

Service: Sodium Hypo , V type

In service since 2013.

Techlink Flow Control Valve V type consist of SAFI Valve PVDF/FKM (VITON), Samson Positioner, Max-Air Actuator.