MANUAL VALVES

Integral flanged ball valves that improve your process profitability

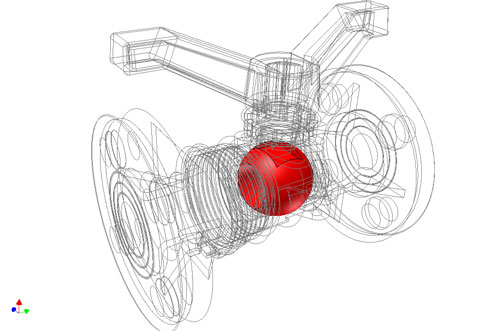

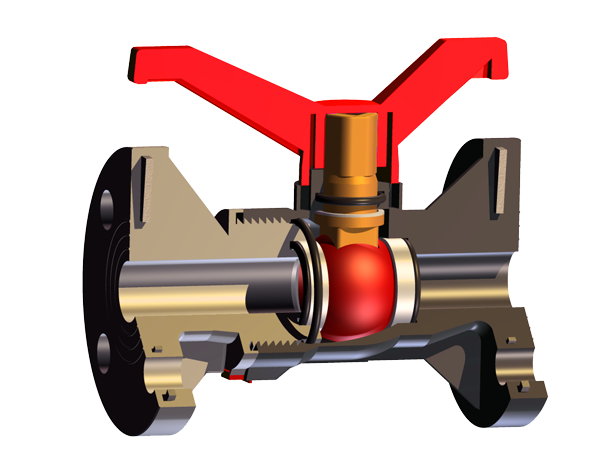

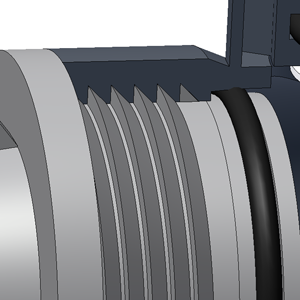

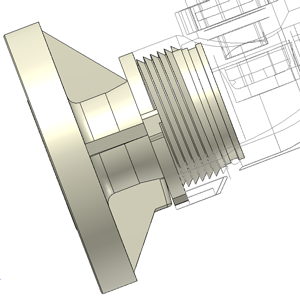

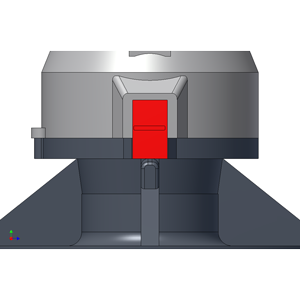

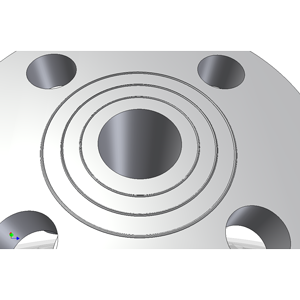

SAFI’s integral flanged ball valves form a family of extremely robust and reliable valves for use with corrosive chemicals such as strong acids and alkalies. They offer good alternatives to alloy ball valves, lined steel diaphragm valves and lined plug valves, so long as the temperature remains below a defined limit.

In some services, they outperform valves made of special metals, such as Alloy 20, chromium cast iron, titanium etc.

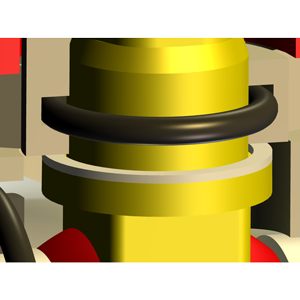

Their resistance to abrasion is good, and they generally perform better in slurries than PTFE lined diaphragm valves. The valves received TA-Luft and ISO 15848 certification. Food grade and ATEX compliant grades are available.

Flanges compatible with DIN, ANSI, BS and JIS standards are available. The valves are also available with face to face dimensions compatible with most diaphragm valves on the market to allow easy substitution.

Economical with an attractive price and low maintenance.

Erosion and corrosion resistant.

Lightweight and high mechanical strength.

Resistant to UV light for outdoors use

Extremelly durable (designed for 40 years lifetime

Why our valves are better than the classic valve solutions

The corrosion resistance of metals is generally determined in still fluids. But at high flow speeds and in the presence of turbulence, a process known as “erosion induced corrosion” starts destroying even the so-called “corrosion resistant” metals. In such situation, solid polymers offer an economic solution that will outperform even “special metals” and other exotic materials.

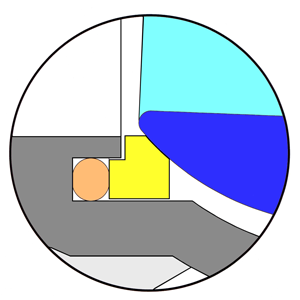

SAFI ball valves features & benefits

An outstanding mechanical resistance. This test illustrates the exceptional mechanical strength of the SAFI glass and steel reinforced integral flanged polypropylene ball valves. This 6″ valves holds a weight of 250kg at the end of 1m section of pipe. It will not break until the weight exceeds 960kg.

Applications

Industries:

- Chlor-Alkali Plants

- Water treatment plants

- Paper pulp mill

- Battery materials plant

Typical fluids:

- Brine

- Wet chlorine

- Hydrochloric acid

- Caustic soda

- Sodium carbonate

- Sodium hypochlorite

- Ferric chloride

- Zinc sulfate

- Copper chloride

- Sodium chlorate

- Sulfuric acid

- Chlorine dioxide

- Sodium sulfite

- Bromine

- Lime water

- Aqua regia

- Copper sulfate

- And more!